Water Well Drilling Rigs Selected for Sand-Dust Regions in 2025

In dusty, arid areas like China’s Northwest, the environment is brutal. It’s hot, dry, the ground is a mix of loose sand, gravel, and hard rock, and the air is full of abrasive dust. This makes drilling tough, so you need a water well rig that’s a real workhorse.

Challenges and selection principles for drilling rigs in sandy areas.

1. Grinding Dust: Sand and fine particles get everywhere—the engine, hydraulic system, and drilling tools—wearing them out super fast.

2. Extreme Weather: High heat and huge temperature swings mean your machine needs top-notch cooling to run reliably all day long.

3. Tricky Ground: You're constantly hitting soft sand, then big rocks, then hard bedrock. The rig needs to be powerful and versatile to handle all of it.

When Choosing a Water Well Drilling Rig for Sandy Areas, You Should Follow These Principles.

1. Dust-Proofing is Key: Every critical part must be sealed well and have multiple layers of filters to keep the dust out.

2. Power & Torque: The rig needs serious muscle (power and torque) to drill deep and chew through hard rock.

3. Built to Last: Drill pipes and structural parts must be made from high-strength, wear-resistant steel. They need to handle a beating.

4. Stay Cool: A robust cooling system is essential for non-stop operation in high temperatures.

5. Multi-Talented: The best rigs can easily switch between drilling methods, like using an air DTH hammer (for rock) and mud circulation (for sand).

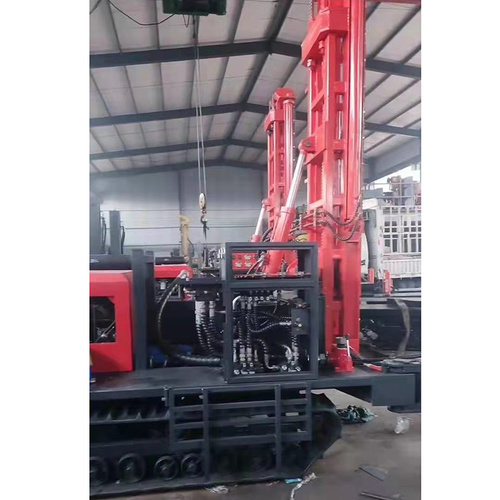

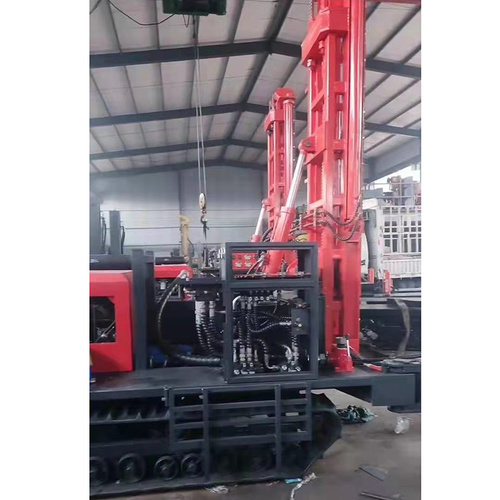

Pearldrill Water Well Drilling Rigs Tackle Dusty Environments

1. Next-Level Dust Protection

Advanced Air Filters: They use a multi-stage system—like a cyclone or oil-bath pre-filter combined with a high-precision main filter—to screen out over 99% of airborne dust before it reaches the engine and air compressor.

Reinforced Sealing: All the sensitive areas, like hydraulic joints, control boxes, and the engine compartment, are specially sealed to prevent dust intrusion.

2. High Performance & Durability

Custom Power: They use powerful engines and air compressors specifically sized for the demanding work in these areas, ensuring consistent performance.

Tough Tools: Their drill pipes and hammers are made from special heat-treated, wear-resistant steel. This significantly extends their life in sandy, abrasive ground and saves you money on replacements.

3. Easy to Use & Fix

Simple Maintenance: The rigs have a modular design, making them quick and easy to take apart and repair in the field.

Centralized Lube (on some models): This automatically lubricates key points, reducing the time and hassle of manual maintenance.

2025 Buying Summary

Feature

|

What You Need

|

Why It Matters (The Benefit)

|

Dust System

|

Cyclone/Oil-bath Pre-filter + High-Precision Filter

|

Extends the life of your engine and air compressor.

|

Power

|

Plenty of reserve power and torque

|

Handles deep wells and hard rock without struggling.

|

Drilling Method

|

Compatible with Air DTH & Mud

|

Easily switches between loose sand and bedrock.

|

Cooling

|

Oversized Radiators & Separate Hydraulic Oil Cooler

|

Ensures stable operation non-stop in the heat.

|

Brand

|

Pearldrill or a specialist in harsh environments

|

Guarantees reliability and good after-sales support.

|

In short: Choosing the right rig, like one with Pearldrill's excellent dust-proof and durable design, will make your water projects in arid zones far more efficient and reliable, which is crucial for local water supply and irrigation.

Contact us

Want to Know More About Water Well Drilling Rigs Operation? Contact Us.