PEARLDRILL has a comprehensive range of DTH drill bits to match all conceivable applications. Each bit is made from quality alloy steel, and has been precision machined to produce a perfect body, heat treated to the required hardness, given surface compression for fatigue resistance, and fitted with precision buttons manufactured in-house. These are deigned for specific applications for all rock types, hardness's and condition. Bit life and rate of penetration are the most important criteria in selecting the right bit for a particular application.

DTH Drill bit features:

Fast drilling and retrieval!High efficiency, low labor intensity of workers!

DTH Drill bit usage:

Widely used in earth and stone engineering mining Wells drilling construction projects drilling Wells edge pillar support.

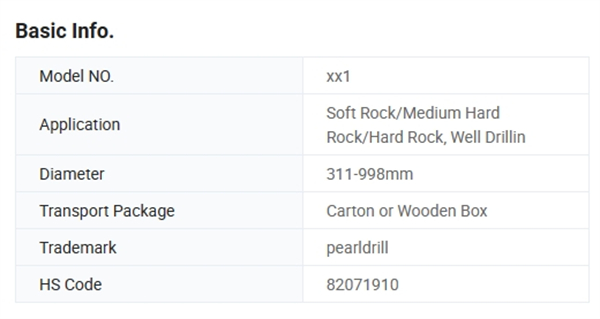

DTH Drill bit model:

Medium/Low wind pressure DTH Drill bit:80 90 100 110 120 130 140 150 180 185 200 220

High wind pressure DTH Drill bit:115 127 138 152 165 178 195 203 216 240 254 304

DTH Drill bit type:

Medium/Low wind pressure DTH Drill bit,High wind pressure DTH Drill bit

DTH hammer model:

Medium/low wind pressure DTH hammer:CIR65 CIR70 CIR90 CIR110 CIR130 CIR150 CIR170 CIR200

High wind pressure DTH hammer:DHD340 DHD350 DHD360 DHD380 N125 SD12

DTH HAMMER application scope:

Widely used in metallurgical, coal, chemical, building materials are not busy mines and water conservancy, hydropower, highway and railway defense construction projects, etc. Suitable for dry wind water mixing and shotgun-hole water gushing wet operation, reliable performance, is the ideal drilling hole and rock drilling equipment.

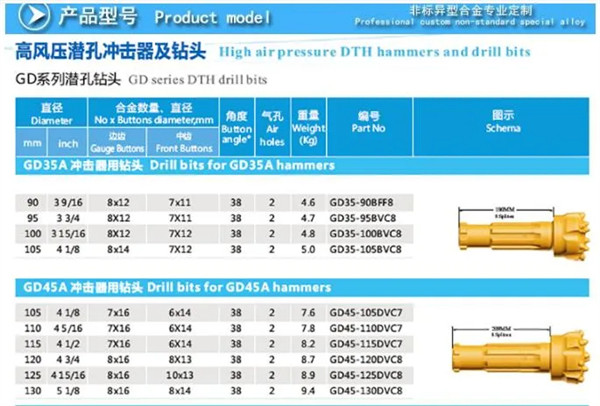

| Drill Diameter | The connection specification | Alloy (star) | Stomates | Weight(KG) | Notes |

| 50 | 29×4 | 5 | 1 | 1 | With type 50 hammer |

| 65 | 37×4 | 6 | 1 | 1.4 | With type 60 hammer |

| 76 | 44×4 | 8 | 2 | 2.2 | With type 70 hammer |

| 80 | 50×6 | 8 | 2 | 3.2 | With type 80 hammer |

| 90 | 54×6 | 10/11 | 2/3 | 3.9 | With type 90 hammer |

| 100 | 54×6 | 10/11 | 2/3 | 4.1 | With type 90 hammer |

| 110 | 54×6/60×4/65×6 | 13 | 2/3 | 6.0 | With type 90/100B/110 hammer |

| 120 | 54×6/60×4/65×6 | 12/13 | 2/3 | 6.2 | With type 90/100B/110 hammer |

| 130 | 54×6/60×4/65×6 | 15 | 3 | 7.2 | With type 90/100B/110 hammer |

| 140 | 60×4/65×6 | 15 | 3 | 7.9 | With type 100B/110 hammer |

| 145 | 60×4/65×6 | 16 | 3 | 8.2 | With type 100B/110 hammer |

| 150 | 60×4/65×6/90×6 | 16/20 | 3 | 8.6-19.8 |

With type 100B /110/150 hammer |

| 160 | 65×6/90×6 | 20/21 | 3 | 19.3 | With type 110/150 hammer |

| 170 | 65×6/90×6 | 20 | 3 | 19.8 | With type 110/150 hammer |

| 175 | 65×6/90×6 | 20/21 | 3 | 20 | With type 110/150 hammer |

| 180 | 65×6/90×6 | 20 | 3 | 21.6 | With type 110/150 hammer |

| 200 | 90×6 | 20 | 3 | 24 | With type 150 hammer |

| 105 | 64×8 | 13 | 2 | 8 | With type 340 hammer |

| 115 | 64×8 | 13 | 2 | 8.5 | With type 340 hammer |

| 140 | 82×8 | 14 | 2 | 12 | With type 350 hammer |

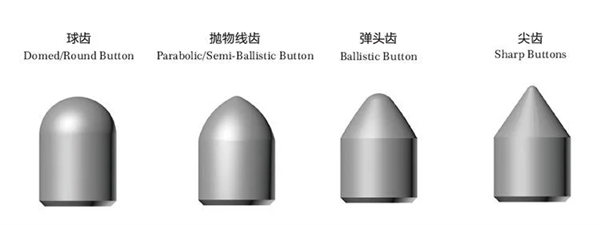

The ball tooth:

It is mainly used for DTH drill bit edge teeth, suitable for very hard rocks with strong abrasivity.

Parabolic tooth:

It is mainly used in DTH drill bit side and middle teeth, suitable for rocks with medium and hard wear.

Warhead tooth:

It is mainly used in DTH drill bit middle teeth, suitable for abrasive medium hardness medium rocks. The soft rock can also be made edge teeth.

Sharp tooth:

Mainly used in DTH drill bit middle teeth, suitable for soft rocks with high drilling speed and low tooth fracture rate.

1.Due to the special internal structure of the DTH hammer designed according to the latest drilling theory, it can provide the maximum energy for the bit, with high drilling speed and low gas consumption.

2.Due to the use of high-quality alloy steel materials and advanced processing technology, the performance of DTH hammer is stable and its service life is long.

3.Because of the simple and reliable internal structure, the hammer is easy to disassemble, low failure rate and easy to maintain.

4.Due to the multi thread connection of chuck and hydraulic cylinder, it is easy to separate the drill from the hammer.

5.Interchangeable with DTH bit and drill pipe.Our company provides low pressure DTH Drill bits and off center DTH Drill bits.

We can make different specifications and different forms of alloy ball bit according to different needs of users.It is widely used in mining, tunnel excavation, underground plant excavation and other construction sites.It is an ideal substitute for the same type of ball bit abroad, with stable quality and high cost performance.

Contact: Mr Chen

Phone: +86 18574606855

Tel: +86 746 8323309

Email: pearldrill02@guangzhouintl.com

Add: Shanhuxi Road, Chuangfacheng Plaza, Yongzhou City ,Hunan Province China