Three Key Preparations Before Operating a Water Well Drilling Rig in 2025

Getting a water well Drilling Rig ready for action in 2025 is way more than just kicking the tires. Thanks to better tech and stricter safety standards, the prep work has become this really integrated process that mixes digital planning, smart systems, and super-thorough safety management. Basically, doing all this detailed groundwork is the non-negotiable key to drilling safely, efficiently, and successfully. The whole preparation process breaks down into three main buckets: Site Survey & Digital Planning, Equipment & System Checks, and Safety & Emergency Readiness.

Site Survey & Digital Planning

1. Geological Data Deep Dive:

We review all the water-geology reports, data from nearby wells, and old exploration cores. We're focused on the depth of the aquifer, where the hard rock is, and any weak spots like fracture zones.

Digital Modeling: We use geophysical data to build a high-resolution 3D model of the subsurface. This helps us predict complex formations and potential risks before the bit even turns.

2. Well Location & Site Setup:

Based on the 3D model and water needs, we pick the absolute best spot. We make sure we avoid things like underground pipes or high-voltage cables.

We plan out the access routes for the rig, the spots for the mud pit, rock cuttings piles, and where the water and power will come from. The site has to be level, well-drained, and environmentally sound.

3. Detailed Drilling Design:

We use the predicted geology to determine the total depth, the well diameter, and the casing structure (how deep and what size the protective pipe will go).

We finalize the drill string combination—meaning we pre-select the most efficient drill bits and downhole tools (like hammers) for the different rock layers we expect to hit.

We design the drilling fluid (mud) system and its properties, making sure it can properly carry cuttings, stabilize the hole, and cool the bit at every stage.

Rig and Tool System Check

1. Power & Drive Systems:

Check the engine (diesel/electric)—fuel, oil, coolant. Make sure it fires up right away.

Check the hydraulic system—oil level, pressure, and all the lines. No leaks, and the hydraulic fluid must be clean.

Inspect the crown, block, drawworks (the hoist), the brakes, and the wire rope. All moving and load-bearing parts must be perfect, and the brakes must be 100% reliable.

2. Drilling Tools & Breaking System:

Inspect all drill pipes and collars—check the threading, wear, and straightness. Absolutely no cracked or overly worn tools allowed.

Check and install the required drill bits, downhole hammers, or other composite tools. Make sure they are secured tightly and working properly.

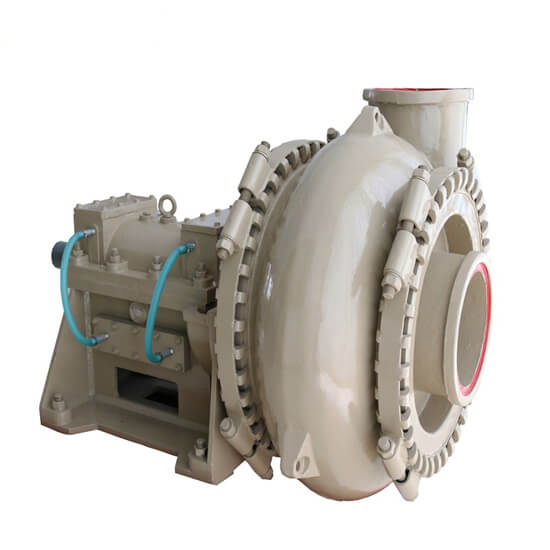

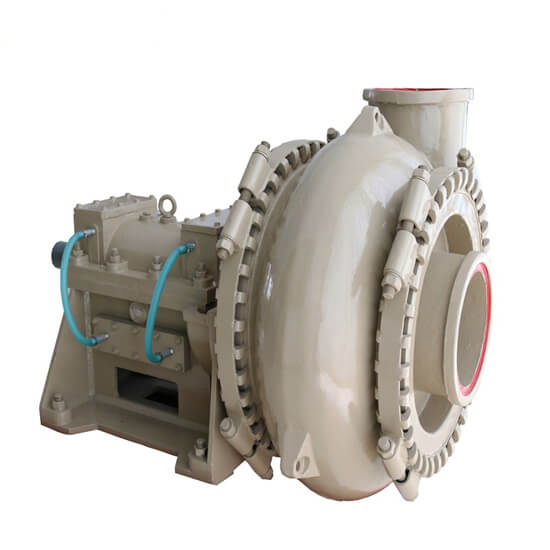

3. Mud/Air Circulation System:

Check the Mud Pump (or air compressor) working condition, seals, and high-pressure manifold.

Check the capacity of the mud pits or air tanks. Make sure we have plenty of drilling fluid materials or compressed air on hand for the job.

4. Safety & Automation Systems (This is the 2025 focus):

Measurement/Monitoring Systems: Check that all the sensors (like those for weight-on-bit, torque, RPM, and vibration) are calibrated and communicating data in real-time. We need to see what's happening downhole.

Check the reliability of the blowout preventer (BOP) at the wellhead and its control system. These critical safety items must be ready to go.

Safety, Environment, and Emergency Readiness (The Human Factor)

1. Crew Briefing & Roles:

Everyone on site gets a detailed safety briefing and technical training before we start. They must know the operation procedures and emergency steps.

Clear roles, responsibilities, and teamwork flows are established for every shift.

Check all personal protective equipment (PPE)—hard hats, safety boots, gloves—to make sure it's all there and up to standard.

2. Fire & Emergency Gear:

Check that the fire extinguishers are correctly placed and not expired.

Make sure the first-aid kit, communication gear, and marked escape routes are ready.

3. Environmental Measures:

Confirm that the mud pits or wastewater collection systems have proper liners to prevent drilling fluid from polluting groundwater or soil.

Have a plan for handling the rock cuttings (waste), ensuring all drill waste is disposed of safely and properly according to local environmental laws.

4. Risk Scenarios:

Create highly specific emergency response plans, especially for high-risk accidents like stuck pipe, blowouts, formation collapse, or toxic gas release.

In Summary:

Getting a water well drilling rig ready in 2025 is all about combining advanced geological prediction, rigorous equipment maintenance, and comprehensive safety management. It's not just a checklist; it's how we execute the modern drilling philosophy of 'Safety First, Efficiency Always.' You have to do this prep right to lay the solid foundation for a successful well, especially when dealing with complex ground conditions."

Contact us

Want to learn more about well drilling irrigation? Click the link and contact us now!