Improper Oil/Fuel Storage Practices for Water Well Drilling Rigs in 2025

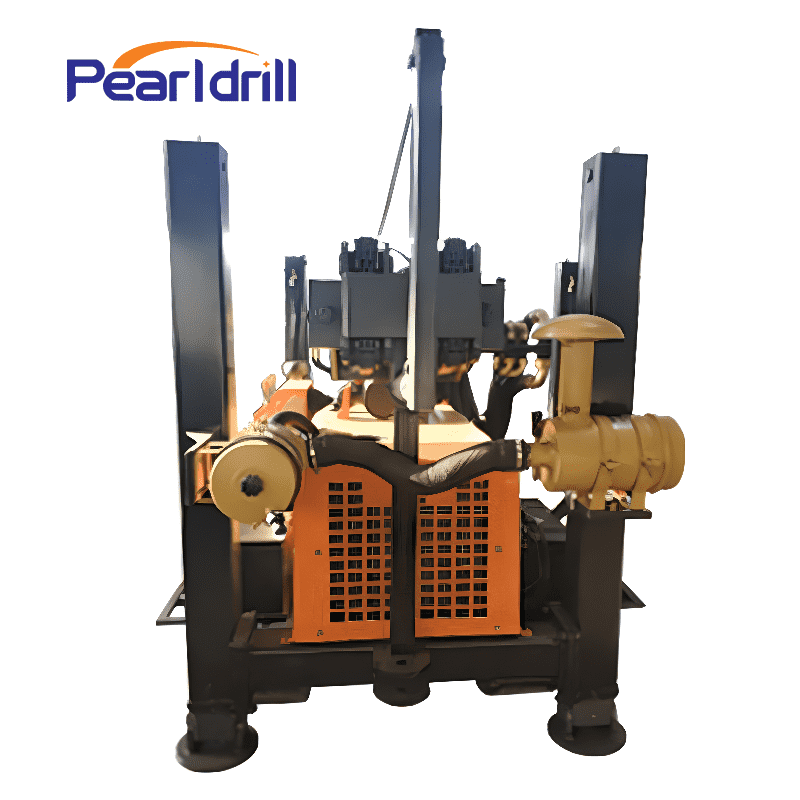

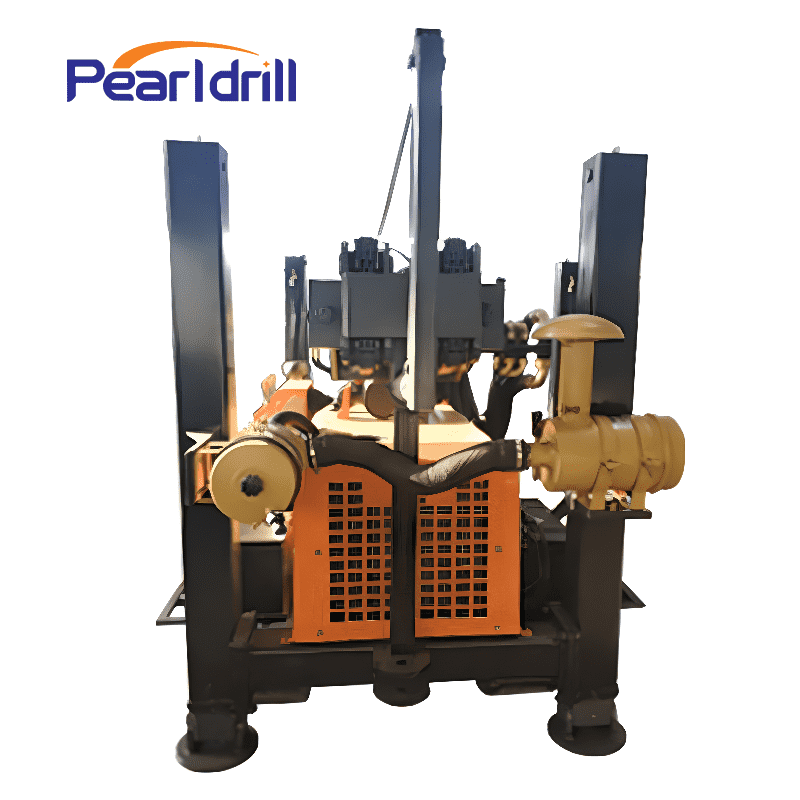

Even in 2025, with all our new tech, managing fuel and oil for water well Drilling Rigs is still a huge blind spot on many job sites. Oil—that's your diesel, lube oil, and hydraulic oil—is the "blood" that keeps your Pearldrill rig running smoothly and efficiently. Mess up the storage, and you risk a big financial hit, major safety hazards, and environmental trouble.

Common Oil Storage Mistakes and Why They Matter

1. Poor Storage Environment:

Heat/Direct Sun: Oil breaks down and oxidizes faster in the heat, which kills its lubrication power. For your Pearldrill's hydraulic system and engine, this means accelerated wear and tear, or even total burnout of components.

Moisture/Outdoor Exposure: Water and humidity can seep in, causing the oil to emulsify (turn milky). This drastically reduces performance and causes corrosion in the rig's sensitive internal parts.

No Fire Safety: Fuel is flammable! Storing it near sparks or electrical equipment is an accident waiting to happen—a serious risk to your crew and your Pearldrill rig.

2. Messy Management:

Mixing Oils: Using the wrong type, or mixing in lowquality oil, will ruin the compatibility of your Pearldrill's systems and cause immediate failures.

Lack of Labels: No one knows what's what! You end up using "expired" or "wrong" oil, significantly shortening the life of your equipment.

Open Containers: Oil drums or tanks left open let dust, dirt, and moisture contaminate the oil, causing massive wear on your filters and pumps.

The Impact on Your Pearldrill Rig

Hydraulic Failure: Your Pearldrill's hydraulic system needs extremely clean oil. Contaminated hydraulic fluid will cause your pumps, motors, and valves to grind down or seize up. This directly kills your drilling speed and pulling power.

Engine Problems: Dirty diesel or poor lube oil can clog the fuel injectors, cause poor combustion, and reduce engine power. Longterm, this leads to severe issues like piston scoring (cylinder wear) and damaged crankshafts.

Big Safety Risk: Leaking oil or builtup vapor can easily ignite from a spark or open flame, leading to fire or explosion.

2025 Oil Storage Best Practices

1. Set Up a Proper Storage Area:

Dedicated Space: Use a separate, fireproof, and wellventilated storage room or shed. Keep it far away from living areas and highheat sources.

Containment is Key: The ground should be paved and impermeable. Install a bund wall or spill containment trays to catch any leaks and prevent soil/groundwater contamination.

Control the Climate: Keep the area out of direct sunlight and ideally at a stable, cool temperature (like below 40℃/104°F). Keep it dry!

2. Implement Strict Oil Management:

Label Everything: Clearly label all oils by name, type, grade, date of delivery, and expiration. Store different types in separate sections.

"First In, First Out" (FIFO): Use the oldest oil first to avoid using oil that's been sitting for too long.

Seal and Protect: Always keep drums and containers tightly sealed. Use only clean, dedicated tools when transferring oil to prevent contamination.

3. Focus on Safety & Environment:

Fire Safety Gear: Make sure the storage area is equipped with the right amount of fire extinguishers and sand buckets.

Train Your Team: Regularly train your staff on proper oil handling, storage safety, and the specific oil requirements for your Pearldrill equipment.

The Takeaway:

In 2025, taking oil storage seriously is the most straightforward way to protect your investment (your Pearldrill rig!), boost project efficiency, and ensure a safe, clean work site. Manage your oil right, and your advanced equipment will perform its best!

Contact us

Want to Know More About Water Well Drilling Rigs Operation? Contact Us.