How to Prevent a Water Well Rig's Drill Pipe from Breaking Downhole in 2025

In 2025, a water well Drilling Rig's drill pipe breaking downhole has gone from a common accident to a preventable risk, all thanks to smart technology and systematic management. As drilling goes deeper and into more complex geology, the integrity of the drill pipe is key to making sure a job is safe and efficient. To prevent a drill pipe from breaking, you need to build a complete prevention system that covers three stages: pre-drill inspection, real-time monitoring while drilling, and drill tool maintenance management.

Before Drilling: High-Precision Inspection and Smart Selection

1. Smart Nondestructive Testing (NDT): In 2025, NDT for drill pipes is highly intelligent. Using phased array ultrasonics and eddy current testing, every single drill pipe gets a "health check." These smart devices can find tiny cracks, fatigue damage, and corrosion spots that you can't see with your eyes. An AI system analyzes this data and gives each pipe a "health score" and a life expectancy. This helps the team get rid of risky pipes before they're ever used, stopping the problem at the source.

2. Geology-to-Tool Matching System: In 2025, drilling companies don't just rely on guesswork to pick a drill pipe. They use a geological big data analysis system that automatically recommends the best drill pipe material, wall thickness, and joint type based on the target formation's hardness, complexity (like faults or caverns), and drilling depth. For example, in hard rock, the system suggests using a high-strength alloy steel pipe, while in a highly corrosive area, it recommends a pipe with a corrosion-resistant coating.

While Drilling: Real-Time Monitoring and Smart Alerts

1. Real-Time Torque and Downward Pressure Monitoring: This is the most direct data you have to figure out what's happening downhole. Modern rigs have highly sensitive sensors that constantly monitor drill pipe torque and downward pressure. When the drill bit hits an obstacle, gets stuck in rock, or the wellbore collapses, the torque will spike or drop suddenly. The smart system immediately catches these anomalies and sends a warning to the operator, who can then adjust drilling parameters to prevent the pipe from twisting or breaking from being overloaded.

2. Vibration and Fatigue Monitoring: A drill pipe is constantly under torsional and bending stress downhole. In 2025, smart rigs have tiny vibration sensors installed near the drill pipe connections or the drill bit. These sensors monitor the pipe's vibration patterns in real time. An abnormal vibration pattern is often a warning sign of pipe fatigue or the drill getting stuck downhole. The AI system analyzes this data to predict the fatigue level of the pipe and warn you before it actually breaks.

After Drilling: Detailed Maintenance and Data Tracking

1. Detailed Cleaning and Upkeep: After every run, the drill pipe needs to be thoroughly cleaned. In 2025, automated cleaning systems can clear away mud and debris from the inside and outside of the pipe and apply a protective coating. At the same time, the threads on the pipe joints get professional maintenance and lubrication to ensure a tight connection for the next job, which prevents breaks caused by wear.

2. Lifecycle Management System: Every drill pipe has its own unique "ID." Internet of Things (IoT) technology ensures that data like each pipe's manufacturing date, number of uses, drilling depth, and stress levels are all logged in a cloud database. This lifecycle management system can create a detailed "health report" for every pipe, accurately telling the team which ones need to be fixed or retired. This removes the risk of relying on guesswork.

From the Above, We Can Conclude the Following:

In 2025, preventing a water well rig's drill pipe from breaking downhole has gone from a reactive problem to a proactive science. By using high-precision pre-drill inspection and smart selection, real-time monitoring while drilling, and detailed lifecycle management after the job, we can build a strong safety barrier. This minimizes the risk of a drill pipe breaking and ensures that water well drilling is safe, efficient, and sustainable.

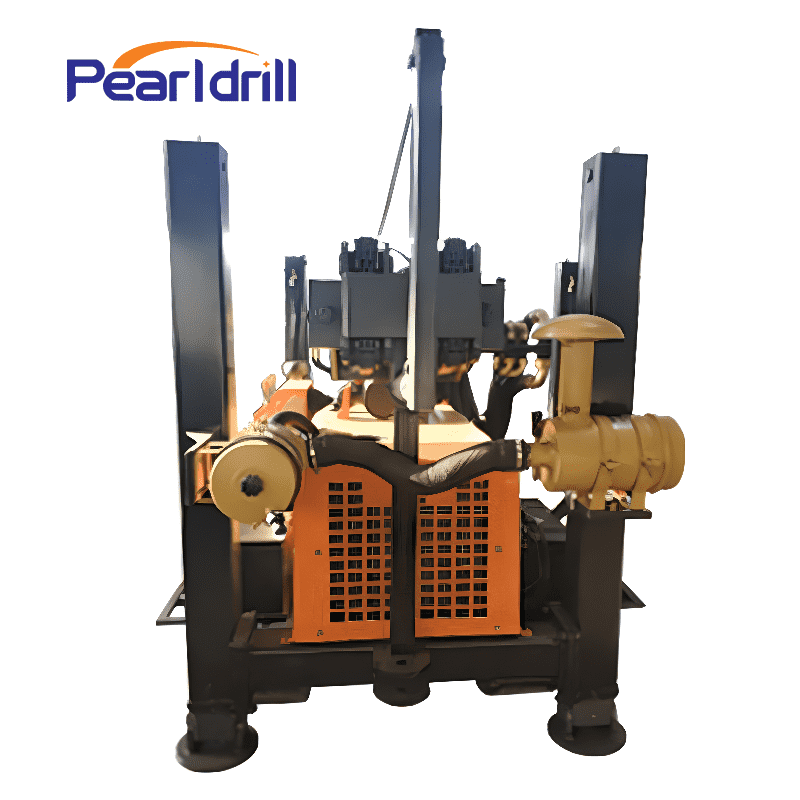

Contact us

To learn more about Chinese water well drill rigs, click the link and contact us.